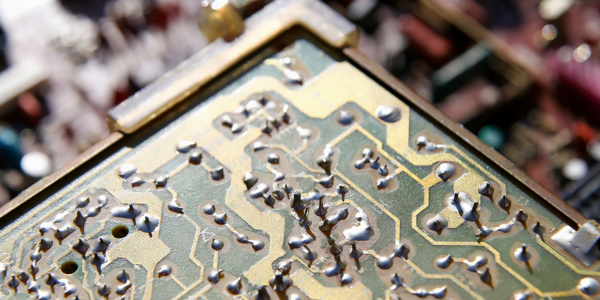

Due to several factors, including the Covid 19 epidemic, microchip fabrication around the world has slowed down dramatically. And because so many people started to work from home in 2021, devices that use certain kinds of microchips surged in demand. This combination of factors has caused a global chip shortage that is likely to last well into 2023.

Even industries that have paid a premium to secure fabrication time are well behind the curve. Semiconductor manufacturers have seen Covid outbreaks in their factories, a moratorium on new building activity due to power requirements in several countries, and shipping issues that plague their development cycles.

So what is the scope of this chip shortage, and what can be done?

What Chips Are Impacted By The Shortage?

Things such as port closures impact every industry, of course. But the addition of semiconductor shortages has had a broad impact on just about every technology chain across the world.

Hardest hit has been the car and truck manufacturing industry, who are seeing six to nine month waits on their fab timeslots. They need millions of lower cost, lower priority chips that are nonetheless integral to their designs. The used car market has shot through the roof as a result.

But everyone who manufactures routing equipment, smart building components, laptops, motherboards, and mobile devices has experienced the squeeze in recent months. Costs are soaring. Taiwan is under so much pressure right now, it’s unlikely that they will get out from behind their backlog for another two years.

What Adaptations Can Be Made?

The first and most obvious adaptation for consumers is to follow the lead of the car industry: Buy used.

In this case, we’re talking about refurbished goods rather than going onto Ebay and dealing with a shady scalper trying to push old Cisco routers at you. Refurbished and certified pre-owned options are available for many brands of networking hardware, laptops, and mobile devices. If they carry the same warranty as the new product, refurb devices are a good way to cut costs and shipping time during this global crisis.

Similarly, smart building and automation hardware is seeing a surge of pre-owned hardware hitting the market. Some of this is because, sadly, certain businesses could no longer function under the restraints of the global pandemic. Other reconditioned inventory is due to companies repairing a backlog of their returned hardware rather than waiting for chip fabrication to ramp back up.

IoT devices, big and small, are not immune to this trend. Things like IP cameras, smart thermostats, and multimedia controllers are all being repaired and recertified due to the chip shortage. Comms equipment like Cisco phones and video conferencing solutions are also going through intense repair and recertification cycles.

The secondary market is also a possibility, but the number of Ebay and other online market scams has skyrocketed during the pandemic. Consumers saw over £1.2 billion worth of fraud in the U.K. alone. That makes the secondary market even more risky and frustrating than it was in relatively normal conditions.

Of course, one thing that everyone has gotten used to over the past few quarters is going virtual whenever possible. Utilizing Cloud based services that don’t require dedicated hardware might not be possible for most smart building solutions, but may replace things like dedicated video conferencing rooms with Zoom style distributed camera and microphone meetings.

A final alternative is switching to smaller electronics vendors who have a supply backlog or a robust parts supply pool from prior to the pandemic. As long as they can comply with all of the compatibility standards of major brands, they are a viable option.

What Is The Industry Doing?

In the long term, reliance on a single small country for most of the world’s semiconductor production is a horrible idea. So the industry is actively building new fabrication plants around the world that should be online in a few years. Although this won’t help in the short term, it will create a more distributed risk profile for future global events.

Intel is securing a new fabrication plant in Ohio. They’re also planning a massive EU expansion, considering Germany, France, and Poland. Micron is looking at Texas as their next fabrication site. Cambridge based PragmatIC Semiconductor is planning an £80 million U.K. expansion after their latest funding round.

Similar scenes are happening throughout the world. Decentralizing Taiwan’s stranglehold on semiconductor production, even if it costs a little bit more per chip, is now being considered a sovereignty and national security issue in many countries.

But industry moves will only help in the long term, with even the smallest new fabrication plants not due to come online for years. In the short term, the main solution is flexibility: Be aware of the certified pre-owned and used hardware options that are on the table, and try to arrange upgrades and expansions as far in advance as possible.